CORE_COMPETENCE

Product_Leaders

index_more

index_more_content

info_item01

info_item_content01

info_item02

info_item_content02

info_item03

info_item_content03

info_item04

info_item_content04

NEWS

NEWS

What are the development trends in the capacitor manufacturer industry?

Development Trends in the Capacitor Manufacturer Industry

I. Introduction

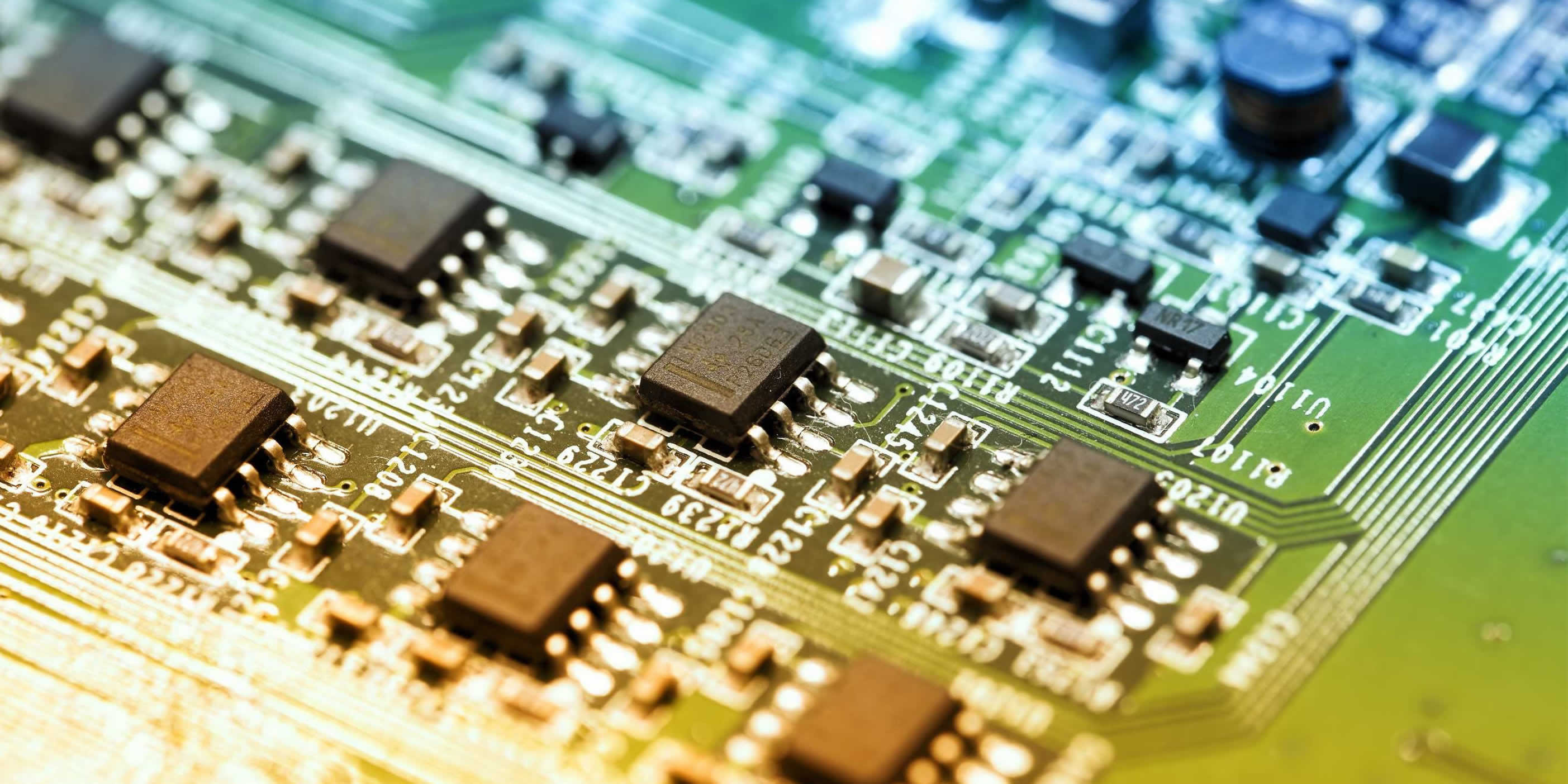

Capacitors are essential components in electronic devices, serving as energy storage units that help regulate voltage and power flow. They play a critical role in various applications, from consumer electronics to industrial machinery, making the capacitor manufacturing industry a vital sector in the global economy. This article aims to explore the development trends in the capacitor manufacturing industry, examining historical contexts, current market landscapes, technological advancements, market drivers and challenges, and future predictions.

II. Historical Context

The history of capacitor technology dates back to the 18th century with the invention of the Leyden jar, one of the first capacitors. Over the years, capacitor technology has evolved significantly, leading to the development of various types of capacitors, including ceramic, electrolytic, film, and tantalum capacitors. The manufacturing processes have also advanced, transitioning from manual assembly to automated production lines, which have increased efficiency and reduced costs. Key milestones in the industry include the introduction of new dielectric materials and the miniaturization of capacitors, enabling their use in increasingly compact electronic devices.

III. Current Market Landscape

A. Overview of the Global Capacitor Market

The global capacitor market has witnessed substantial growth in recent years, driven by the increasing demand for electronic devices. According to market research, the capacitor market is projected to reach USD 30 billion by 2025, growing at a CAGR of 5.5%. Key players in the industry include companies like Murata Manufacturing, Vishay Intertechnology, and KEMET Corporation, which dominate the market with their innovative products and extensive distribution networks.

B. Types of Capacitors and Their Applications

Capacitors come in various types, each suited for specific applications:

1. **Ceramic Capacitors**: Widely used in consumer electronics, these capacitors are known for their stability and reliability.

2. **Electrolytic Capacitors**: Commonly found in power supply circuits, they offer high capacitance values and are essential for filtering applications.

3. **Film Capacitors**: Known for their low losses and high insulation resistance, these capacitors are used in audio equipment and power electronics.

4. **Tantalum Capacitors**: These capacitors are favored in military and aerospace applications due to their reliability and performance in extreme conditions.

C. Regional Market Analysis

The capacitor market is geographically diverse, with significant activity in North America, Europe, and the Asia-Pacific region. North America is home to several leading manufacturers and benefits from a strong consumer electronics market. Europe is focusing on sustainable manufacturing practices and compliance with environmental regulations, while the Asia-Pacific region, particularly China, is experiencing rapid growth due to its booming electronics industry.

IV. Technological Advancements

A. Innovations in Capacitor Materials

Recent innovations in capacitor materials have led to the development of new dielectric materials that enhance performance and efficiency. For instance, advancements in polymer and ceramic materials have resulted in capacitors with higher capacitance values and improved thermal stability. Additionally, nanotechnology is being explored to create capacitors with smaller sizes and higher energy densities.

B. Manufacturing Process Improvements

The capacitor manufacturing industry is embracing automation and Industry 4.0 technologies to improve production efficiency. Automated assembly lines and robotics are reducing labor costs and increasing output. Furthermore, sustainable manufacturing practices are gaining traction, with companies focusing on reducing waste and energy consumption during production.

C. Miniaturization and High-Capacity Designs

As electronic devices become smaller and more powerful, the trend towards miniaturization in capacitor design is becoming increasingly important. Manufacturers are developing high-capacity capacitors that can fit into compact spaces without compromising performance. This trend is particularly relevant in the context of smartphones, wearables, and other portable devices.

V. Market Drivers and Challenges

A. Increasing Demand for Electronic Devices

The growing demand for electronic devices is a significant driver of the capacitor manufacturing industry. The rise of consumer electronics, including smartphones, tablets, and laptops, has led to an increased need for capacitors. Additionally, the expansion of electric vehicles (EVs) and renewable energy systems is creating new opportunities for capacitor manufacturers, as these technologies require advanced energy storage solutions.

B. Regulatory and Environmental Considerations

The capacitor manufacturing industry is also facing regulatory and environmental challenges. Compliance with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations is essential for manufacturers to ensure their products are safe and environmentally friendly. There is a growing shift towards eco-friendly materials, prompting manufacturers to innovate and adapt their processes.

C. Supply Chain Challenges

The COVID-19 pandemic has highlighted vulnerabilities in global supply chains, impacting the availability of raw materials and components for capacitor manufacturing. Material shortages and sourcing issues have become prevalent, forcing manufacturers to rethink their supply chain strategies and seek alternative sources for critical materials.

VI. Future Trends and Predictions

A. Growth of Electric Vehicles and Energy Storage Systems

The future of the capacitor manufacturing industry is closely tied to the growth of electric vehicles and energy storage systems. As the demand for EVs continues to rise, capacitors will play a crucial role in power management and energy efficiency. Manufacturers are expected to invest in research and development to create capacitors that can withstand the unique demands of EV applications.

B. The Role of Capacitors in Renewable Energy Technologies

Capacitors are essential components in renewable energy technologies, such as solar and wind power systems. They help stabilize voltage and improve the efficiency of energy conversion. As the world shifts towards sustainable energy solutions, the demand for capacitors in this sector is expected to grow significantly.

C. Emerging Applications in IoT and Smart Devices

The Internet of Things (IoT) and smart devices are creating new opportunities for capacitor manufacturers. As more devices become interconnected, the need for efficient energy storage and management solutions will increase. Capacitors will be integral to the performance of these devices, driving innovation in design and materials.

D. Predictions for Market Consolidation and Mergers

As the capacitor market continues to evolve, consolidation and mergers among manufacturers are likely to occur. Companies may seek to enhance their product offerings and expand their market reach through strategic partnerships and acquisitions. This trend could lead to a more competitive landscape, with fewer but more powerful players dominating the market.

VII. Conclusion

In summary, the capacitor manufacturing industry is undergoing significant changes driven by technological advancements, increasing demand for electronic devices, and evolving regulatory landscapes. The importance of innovation and adaptation cannot be overstated, as manufacturers strive to meet the challenges and opportunities presented by the market. As we look to the future, the capacitor industry is poised for growth, with exciting developments on the horizon that will shape the next generation of electronic devices.

VIII. References

1. Market Research Reports on Capacitor Industry

2. Academic Papers on Capacitor Technology

3. Industry Reports from Leading Manufacturers

4. Articles on Emerging Trends in Electronics and Energy Storage

This blog post provides a comprehensive overview of the development trends in the capacitor manufacturing industry, highlighting the historical context, current market dynamics, technological advancements, market drivers and challenges, and future predictions. Each section is designed to offer insights into the complexities and opportunities within this vital sector.

2025-01-05

0

What product types do capacitors include?

What Product Types Do Capacitors Include?

I. Introduction

Capacitors are fundamental components in the world of electronics, playing a crucial role in the functioning of various devices and circuits. Defined as passive electrical components that store and release electrical energy, capacitors are essential for managing voltage fluctuations, filtering signals, and providing energy storage in a myriad of applications. This article aims to explore the different types of capacitors, their characteristics, and their applications, providing a comprehensive overview of this vital electronic component.

II. Basic Principles of Capacitors

A. How Capacitors Work

At their core, capacitors function by storing electrical energy in an electric field created between two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric charge accumulates, allowing the capacitor to store energy. The amount of energy a capacitor can store is quantified by its capacitance, measured in farads (F).

B. Key Components of Capacitors

1. **Dielectric Materials**: The dielectric is a non-conductive material that separates the plates of a capacitor. Common dielectric materials include air, ceramic, plastic films, and electrolytic solutions. The choice of dielectric affects the capacitor's performance, including its capacitance, voltage rating, and temperature stability.

2. **Plates and Their Arrangement**: The conductive plates can be arranged in various configurations, such as parallel or rolled, to optimize the capacitor's size and capacitance. The surface area of the plates and the distance between them also play a significant role in determining the capacitor's overall performance.

III. Types of Capacitors

Capacitors can be broadly categorized into fixed, variable, supercapacitors, and specialty capacitors, each serving unique functions in electronic circuits.

A. Fixed Capacitors

Fixed capacitors have a predetermined capacitance value that cannot be adjusted. They are widely used in various applications due to their reliability and stability.

1. **Ceramic Capacitors**:

- **Characteristics**: Ceramic capacitors are made from ceramic materials and are known for their small size, low cost, and high stability.

- **Applications**: Commonly used in decoupling and filtering applications, they are found in power supply circuits and RF applications.

2. **Film Capacitors**:

- **Types of Film Capacitors**: These include polyester, polypropylene, and polystyrene capacitors, each with distinct properties.

- **Advantages and Disadvantages**: Film capacitors offer low losses and high stability but can be bulkier than other types.

3. **Electrolytic Capacitors**:

- **Construction and Working Principle**: Electrolytic capacitors use an electrolyte as one of the plates, allowing for higher capacitance values in a smaller size.

- **Common Uses and Limitations**: They are widely used in power supply circuits but have polarity and limited lifespan issues.

4. **Tantalum Capacitors**:

- **Unique Properties**: Tantalum capacitors are known for their high capacitance and stability in a compact form factor.

- **Applications in Modern Electronics**: They are often used in portable devices and applications requiring high reliability.

5. **Mica Capacitors**:

- **Stability and Precision**: Mica capacitors are known for their excellent stability and precision, making them suitable for high-frequency applications.

- **Typical Applications**: They are often used in RF circuits and precision timing applications.

B. Variable Capacitors

Variable capacitors allow for the adjustment of capacitance values, making them essential in tuning applications.

1. **Definition and Function**: These capacitors can change their capacitance by altering the distance between the plates or the effective area of the plates.

2. **Types of Variable Capacitors**:

- **Air Variable Capacitors**: These use air as the dielectric and are commonly found in radio tuning circuits.

- **Trimmer Capacitors**: Small capacitors that can be adjusted for fine-tuning in circuits.

- **Potentiometer Capacitors**: These combine the functions of a potentiometer and a capacitor, allowing for variable resistance and capacitance.

3. **Applications in Tuning and Frequency Modulation**: Variable capacitors are crucial in radio transmitters and receivers, enabling precise tuning of frequencies.

C. Supercapacitors

Supercapacitors, also known as ultracapacitors, are a unique class of capacitors that bridge the gap between traditional capacitors and batteries.

1. **Definition and Characteristics**: Supercapacitors have a much higher capacitance than conventional capacitors, allowing them to store significant amounts of energy.

2. **Comparison with Traditional Capacitors**: While traditional capacitors discharge energy quickly, supercapacitors can deliver energy over a longer period, making them suitable for energy storage applications.

3. **Applications in Energy Storage and Power Delivery**: Supercapacitors are increasingly used in applications such as regenerative braking systems in electric vehicles and backup power supplies.

D. Specialty Capacitors

Specialty capacitors are designed for specific applications, often requiring unique characteristics.

1. **High-Voltage Capacitors**:

- **Design and Applications**: These capacitors are built to withstand high voltage levels and are used in power transmission and distribution systems.

2. **Pulse Capacitors**:

- **Characteristics and Uses**: Designed to handle high-energy pulses, these capacitors are used in applications like laser systems and pulsed power applications.

3. **RF Capacitors**:

- **Importance in Radio Frequency Applications**: RF capacitors are optimized for high-frequency signals and are essential in communication devices.

4. **Motor Run and Motor Start Capacitors**:

- **Role in Electric Motors**: These capacitors help start and run electric motors, providing the necessary phase shift for efficient operation.

IV. Capacitor Selection Criteria

When selecting a capacitor for a specific application, several criteria must be considered:

1. **Capacitance Value**: The required capacitance value depends on the application, influencing the capacitor's size and performance.

2. **Voltage Rating**: The voltage rating must exceed the maximum voltage the capacitor will encounter in the circuit to prevent failure.

3. **Temperature Coefficient**: The temperature coefficient indicates how capacitance changes with temperature, affecting performance in varying conditions.

4. **Size and Form Factor**: The physical size and shape of the capacitor can impact its integration into a circuit, especially in compact designs.

5. **Application-Specific Requirements**: Certain applications may require specific characteristics, such as low ESR (Equivalent Series Resistance) or high-frequency performance.

V. Future Trends in Capacitor Technology

As technology advances, capacitor technology is evolving to meet new demands:

1. **Advancements in Materials**: Research into new dielectric materials is leading to capacitors with improved performance and efficiency.

2. **Miniaturization and Integration in Circuits**: The trend towards smaller electronic devices is driving the development of compact capacitors that can be integrated into circuit boards.

3. **Environmental Considerations and Recycling**: With increasing awareness of environmental issues, there is a push for sustainable capacitor designs and recycling methods to reduce electronic waste.

VI. Conclusion

Capacitors are indispensable components in modern electronics, serving a wide range of functions from energy storage to signal filtering. Understanding the various types of capacitors and their applications is essential for anyone involved in electronics design and engineering. As technology continues to evolve, capacitors will play an increasingly important role in shaping the future of electronic devices, making it crucial to stay informed about advancements in this field.

VII. References

For further exploration of capacitors and their applications, consider the following resources:

1. "Capacitors: Principles and Applications" by John Smith

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

3. Online resources such as IEEE Xplore and Electronics Tutorials for up-to-date research and articles on capacitor technology.

2025-01-03

0

What industries are the application scenarios of pulse capacitors included in?

What Industries Are the Application Scenarios of Pulse Capacitors Included In?

I. Introduction

In the realm of modern electronics, pulse capacitors play a pivotal role in various applications, from telecommunications to renewable energy. These specialized components are designed to store and release electrical energy in short bursts, making them essential for systems that require rapid energy discharge. This blog post aims to explore the significance of pulse capacitors, their operational principles, and the diverse industries that rely on them.

II. Understanding Pulse Capacitors

A. Basic Principles of Operation

Pulse capacitors operate on the fundamental principle of capacitance, which is the ability of a component to store electrical energy. When a voltage is applied, the capacitor accumulates charge, and when the circuit demands a quick release of energy, the capacitor discharges rapidly. This characteristic makes pulse capacitors ideal for applications that require high power in short durations.

B. Types of Pulse Capacitors

1. **Film Capacitors**: These capacitors use a thin plastic film as the dielectric material. They are known for their stability, low loss, and ability to handle high voltages, making them suitable for high-frequency applications.

2. **Ceramic Capacitors**: Utilizing ceramic materials as the dielectric, these capacitors are compact and can operate at high temperatures. They are commonly used in RF applications due to their low equivalent series resistance (ESR).

3. **Electrolytic Capacitors**: These capacitors are polarized and can store a large amount of charge, making them ideal for applications requiring significant energy storage. However, they are less suitable for high-frequency applications due to their higher ESR.

C. Key Characteristics and Specifications

1. **Voltage Rating**: This indicates the maximum voltage the capacitor can handle without breaking down. It is crucial to select a capacitor with an appropriate voltage rating for the application.

2. **Capacitance Value**: Measured in farads, this value indicates the amount of charge a capacitor can store. Different applications require different capacitance values based on their energy needs.

3. **Discharge Time**: The speed at which a capacitor can release its stored energy is vital for pulse applications. Faster discharge times are essential for applications like radar and medical devices.

III. Key Industries Utilizing Pulse Capacitors

A. Telecommunications

In the telecommunications industry, pulse capacitors are integral to signal processing. They are used in RF and microwave systems to filter signals and manage power levels. Their ability to handle rapid changes in voltage makes them essential for maintaining signal integrity in high-frequency applications.

B. Automotive

The automotive industry has seen a significant shift towards electric and hybrid vehicles, where pulse capacitors play a crucial role. They are used in power electronics and control systems to manage energy flow and improve efficiency. Additionally, pulse capacitors are essential in regenerative braking systems, where they store energy during braking and release it when needed.

C. Medical Devices

Pulse capacitors are vital in medical imaging equipment, such as MRI and CT scanners, where they provide the necessary energy for rapid imaging processes. They are also used in defibrillators and other life-saving devices, where quick energy discharge is critical for patient care. The reliability and performance of pulse capacitors in these applications can directly impact patient outcomes.

D. Industrial Automation

In industrial automation, pulse capacitors are used in robotics and control systems to ensure precise operation. They are also employed in power supply and energy storage systems, where they help manage energy distribution and improve system efficiency. The ability to deliver high power in short bursts is essential for the smooth operation of automated processes.

E. Aerospace and Defense

The aerospace and defense sectors rely heavily on pulse capacitors for avionics and navigation systems. These components are used in military equipment and communication systems, where reliability and performance are paramount. The ability to withstand harsh environmental conditions while delivering rapid energy discharge makes pulse capacitors indispensable in these applications.

F. Renewable Energy

As the world shifts towards renewable energy sources, pulse capacitors are becoming increasingly important. They are used in solar inverters and wind turbines to manage energy conversion and storage. Additionally, pulse capacitors play a role in energy storage systems, where they help stabilize power output and improve overall system efficiency.

IV. Emerging Applications and Trends

A. Advancements in Technology

The field of pulse capacitors is witnessing significant advancements, particularly in miniaturization and increased efficiency. As technology progresses, manufacturers are developing smaller, more efficient capacitors that can be integrated into smart technologies. This trend is paving the way for new applications in various industries.

B. Future Prospects in Various Industries

1. **Potential for Growth in Electric Vehicles**: As the demand for electric vehicles continues to rise, the need for efficient energy storage solutions will grow. Pulse capacitors are well-positioned to meet this demand, offering rapid energy discharge capabilities that enhance vehicle performance.

2. **Innovations in Medical Technology**: The medical field is constantly evolving, with new technologies emerging to improve patient care. Pulse capacitors will play a crucial role in the development of advanced medical devices, enabling faster and more efficient operations.

V. Challenges and Considerations

A. Reliability and Longevity

While pulse capacitors are essential in many applications, their reliability and longevity can be a concern. Manufacturers must ensure that these components can withstand the rigors of their operating environments to prevent failures that could lead to costly downtime.

B. Cost Factors

The cost of pulse capacitors can vary significantly based on their specifications and applications. Industries must carefully consider their budget constraints while selecting the right capacitors for their needs.

C. Environmental Impact and Sustainability

As industries become more environmentally conscious, the sustainability of pulse capacitors is an important consideration. Manufacturers are exploring eco-friendly materials and production processes to minimize the environmental impact of these components.

VI. Conclusion

Pulse capacitors are integral to a wide range of industries, providing essential energy storage and discharge capabilities. From telecommunications to renewable energy, their applications are diverse and critical to modern technology. As advancements continue to shape the future of pulse capacitors, industries must remain aware of the challenges and opportunities that lie ahead. Continued research and development in this field will be vital for harnessing the full potential of pulse capacitors and driving innovation across various sectors.

In conclusion, the importance of pulse capacitors cannot be overstated. They are not just components; they are enablers of technology that enhance performance, efficiency, and reliability across multiple industries. As we look to the future, the potential for growth and innovation in this field is immense, and it is essential for stakeholders to invest in further research and development to unlock new possibilities.

2024-12-28

0